Compression molding is often the more economical manufacturing process when working with low volume thermoset resins. The compression molding process provides additional geometry flexibility over standard injection molding and is typically used to produce large, fairly complex parts that are unsuitable for injection molding presses.

Compression molding is only compatible with a select number of thermoset resins. For resins that are compatible, compression molding eliminates molded stresses, produces less wasted material, improves molding cycle speed and significantly reduces tonnage requirements. Modor design engineers can help you decide if compression molding is right for you.

The Compression Molding Process

Thermoset powder is heated to a malleable state, them compressed to a liquid to produce a final shape. This relatively low pressure compression method evenly distributes the resin for uniform strength without damaging the mold, regardless of design complexity.

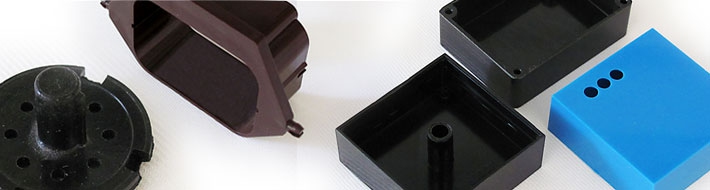

Compression Molding Examples

Compression molding is used for everything from heavy-duty enclosures to light-weight precision parts. Everyday examples of compression molding include optical media, thin-walled electrical parts and cable insulation.

Contact a Modor Thermoplastics design engineer for more information.